Can you cut it...

Yes we can

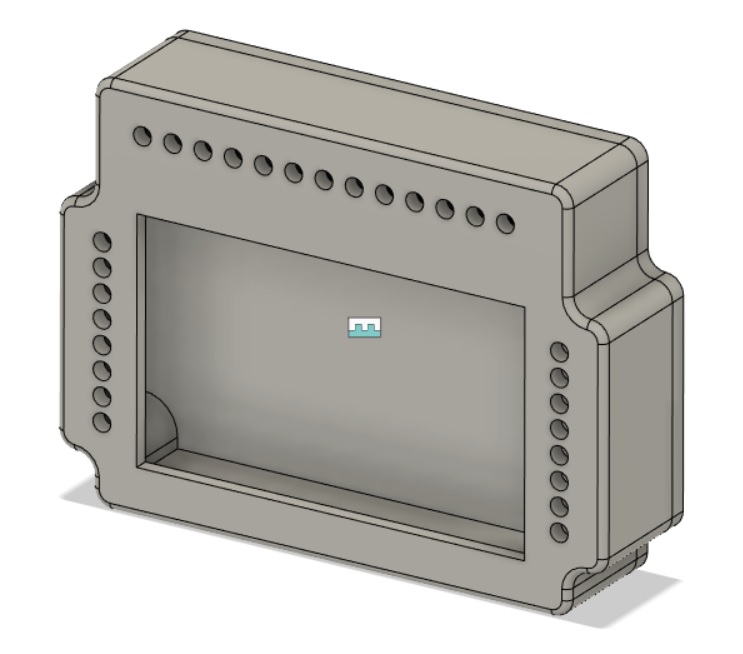

When we need to 3d mill objects – we use the best software in town – Fusion 360.

With Fusion it makes it very easy to create and cut exact shapes you’re after. See how we do it below:

3d shape design

We can help you create complex shapes and assist in making them a 3d reality. We use Fusion360 to model and toolpath 3d shapes.

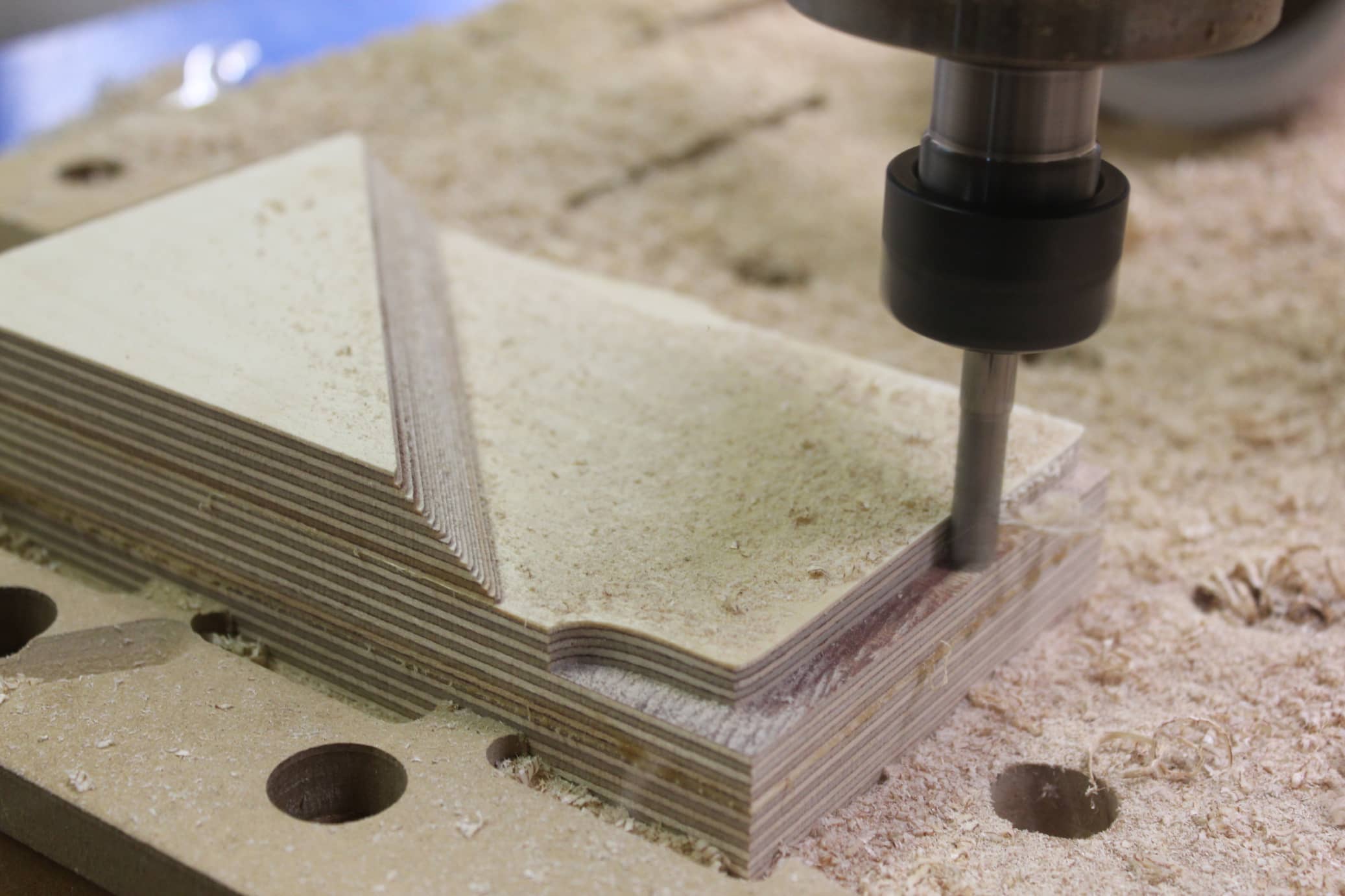

3d roughing

This is the process where by we mill out the bulk of the material we dont need fast. Subtractive manufacturing at its best!

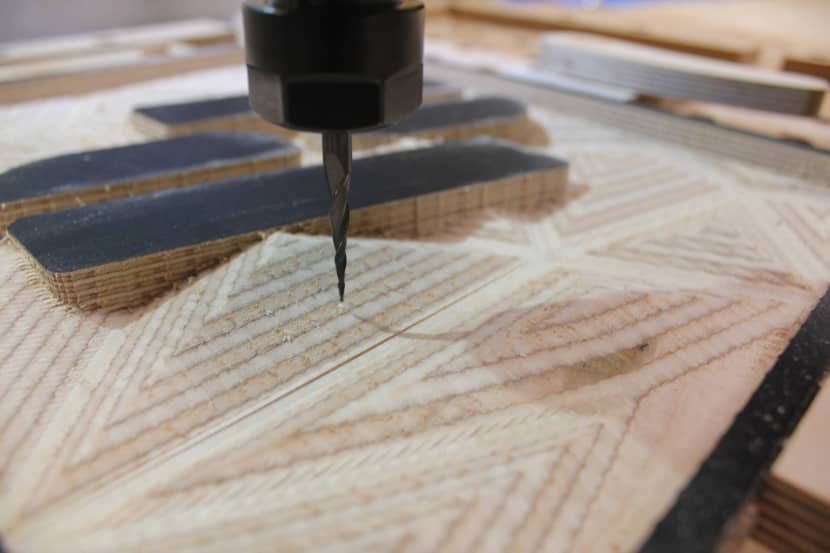

Fine finishing

Once the rough cut is finished we use special round ended cnc bits to mill our a fine smooth finish for the 3d effect to really pop to life.

See how the roughing process works

Here we used a 8mm down cut bit. We had to run mulitple height passes to create a .5mm step down. This would allow for our 1mm ball nose bit to clean it up in the finishing pass!

Featured techniques

smooth curved faces

Achieve precise and exacting shapes with the pwer of our CNC router. These handles were milled in two halves from the same piece of stock. Its called double sided milling. Looks pretty cool don’t you think?

complex angles

If we can CAD a shape, we should be able to cut the shape too. This piece would have been very difficult to cut any other way other than on a CNC router. It angles away at a precise degree and is pitched multiple sides to match a secondary female sliding join.

textured effects

This shell shape is actually a 2d flat stock piece of MDF but through smart toolpath design the effect created makes the object have a 3d feel. In reality the shell is only 18mm thick and the contours simply slope from deep to shallow cut depths.

thread milling

Need to make a decorative wooden thread? Or even metal thread. Yea we’ve done that too…

What Our customers say

We can't wait to work with Carl again and would definitely recommend him for any company looking for everything from design concepting and rapid proto-typing through to final CNC manufacturing.

Dugald Moncrieffs | Manager FE Fabrications

Carl from Playdrive is realy great to work with, being super personable, knowledgeable & responsive in all aspects of his work. Ive had several small projects completed by Carl whos made eash to the exact requirements with improvements and revisions along the way without a fuss. Recommend highly for any work.

Peter Rawlings | Wood Life Crisis